-40%

HEIDENHAIN 336978-C4, LS704, 220395-0415, GLASS SCALE LINEAR ENCODER 10.6" 270MM

$ 224.4

- Description

- Size Guide

Description

HEIDENHAIN 336978-C4 336978C4 220395-0415 LS704 GLASS SCALE LINEAR ENCODER 10.6" 270MM**************************************** FREE SHIPPING!! *******************************************

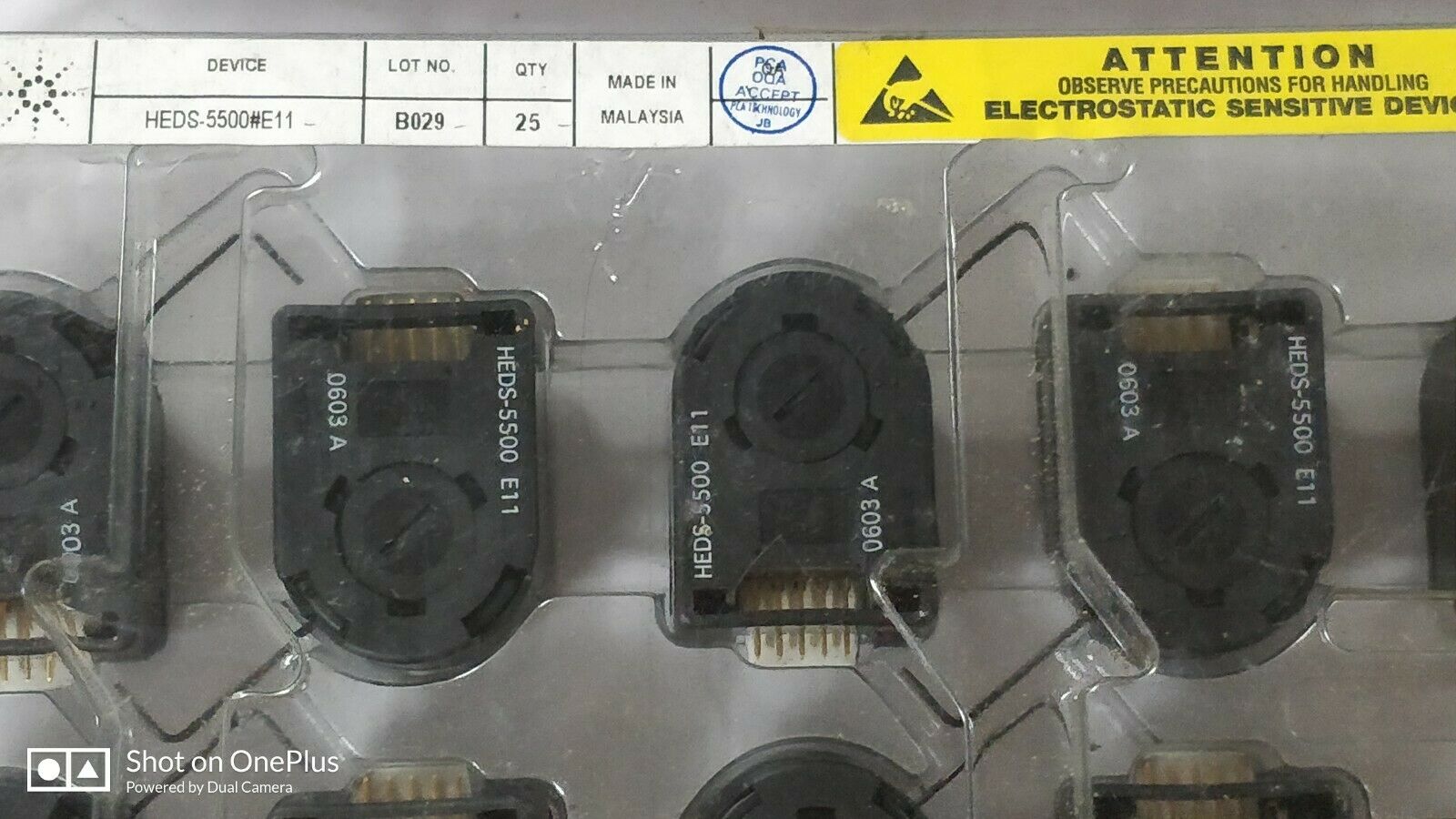

New Old Stock (NOS). Open box with all paperwork and small hardware. See pictures for actual condition. Note, this is for the encoder only (as shown), no cable is provided.

Comes as shown, thanks for looking!!

From the manufacturer:

Linear encoders from HEIDENHAIN for numerically controlled machine tools can be used nearly everywhere. They are ideal for machines and other equipment whose feed axes are in a servo loop, such as milling machines, machining centers, boring machines, lathes and grinding machines. The beneficial dynamic behavior of linear encoders, their high permissible traversing speed, and their acceleration in the direction of measurement predestine them for use on highly-dynamic conventional axes as well as on direct drives.

HEIDENHAIN also supplies linear encoders for other applications, such as:

• Manual machine tools

• Presses and bending machines

• Automation and production equipment Advantages of linear encoders If a linear encoder is used for measurement of the slide position, the position control loop includes the complete feed mechanics. This is referred to as Closed Loop operation. Transfer errors from the mechanics can be detected by the linear encoder on the slide, and corrected by the control electronics. This makes it possible to eliminate a number of potential error sources:

• Positioning error due to thermal behavior of the recirculating ball screw

• Reversal error

• Kinematics error through ball-screw pitch error

Therefore, linear encoders are indispensable for machine tools on which high positioning accuracy and a high machining rate are essential. Mechanical design Linear encoders for servo-controlled machine tools are sealed measuring devices: an aluminum housing protects the scale, the scanning carriage and its guide against chips, dust and splashing water. Downward-oriented elastic lips seal the housing. The scanning carriage travels along the scale on a low-friction guide. A coupling connects the scanning carriage with the mounting block and compensates the misalignment between the scale and the machine guideways. Depending on the encoder model, lateral and axial offsets of ±0.2 mm to ±0.3 mm between the scale and mounting block are permissible.